Centrifugal Blower

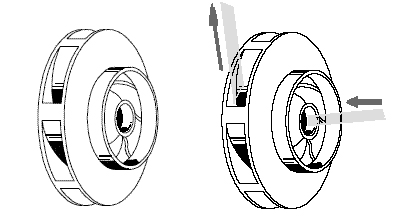

An impeller is attached to a rotating shaft within a cylindrical housing.

Gas drawn into the housing near the centre, is then thrown towards the perimeter.

The imparted velocity of the gas causes a pressure rise and flow.

Multi-stage machines direct the gas back to the centre of the next stage.

| Typical Performance Envelope | ||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

| Advantages | ||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

| Disadvantages | ||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

| Common Applications | ||||||||||||||||||||||||||||